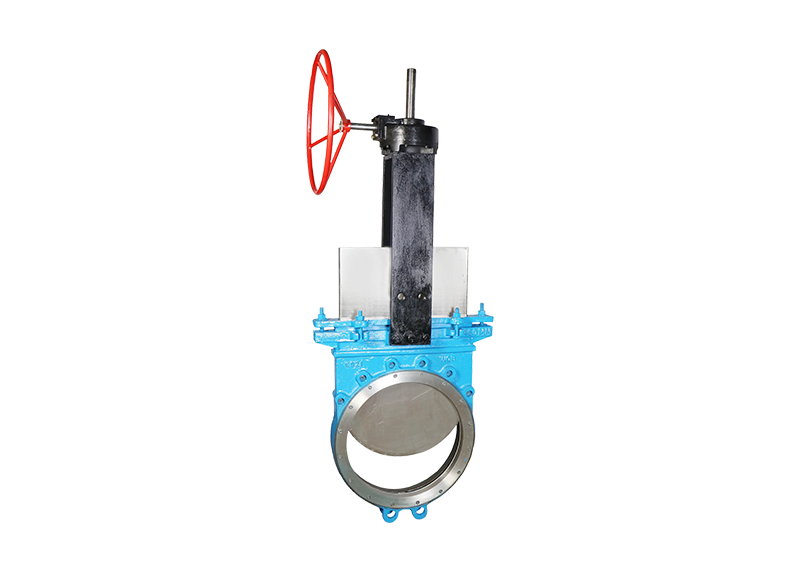

Features

Bi-directional valve designed for general industrial service applications. The design of the body and seat assures non-clogging shutoff on suspended solids in industries such as:

Sizes

- DN 50 to DN 1200 (larger diameters on request)

- Working pressure:

- DN 50 to DN 250: 10 kg/cm²

- DN 300 to DN 400: 6 kg/cm²

- DN 450: 5 kg/cm²

- DN 500 to DN 600: 4 kg/cm²

- DN 700 to DN 1200: 2 kg/cm²

- Standard flange connection:

- ANSI B 16.5 CLASS 150

- Face to face dimensions AS PER MSS SP-81

Benefits

- Knife edge gate design

- Body Bore - Full bore

- Gate - Ground, polished and radiused for low torques and smooth operation

- Stuffing box bore - superior finish for low emission and positive sealing

- Gilded Gate - Cast jams in the body for guiding the gate

- Operation - retrofit from manual to pneumatic

- Pneumatic actuator, limit switch, solenoid valve, air filter regulator, etc.

ANSI CLASS RATING

MSS SP-81

SIZES

50mm (2") to 750mm (30")

MATERIALS

WCB, CF8, CF8M, CF3, CF3M, CN7M, CD4MCuN, etc

END CONNETIONS

Wafer

Lugged

Applications

- Wastewater treatment plants

- Chemical plants

- Food and Beverage