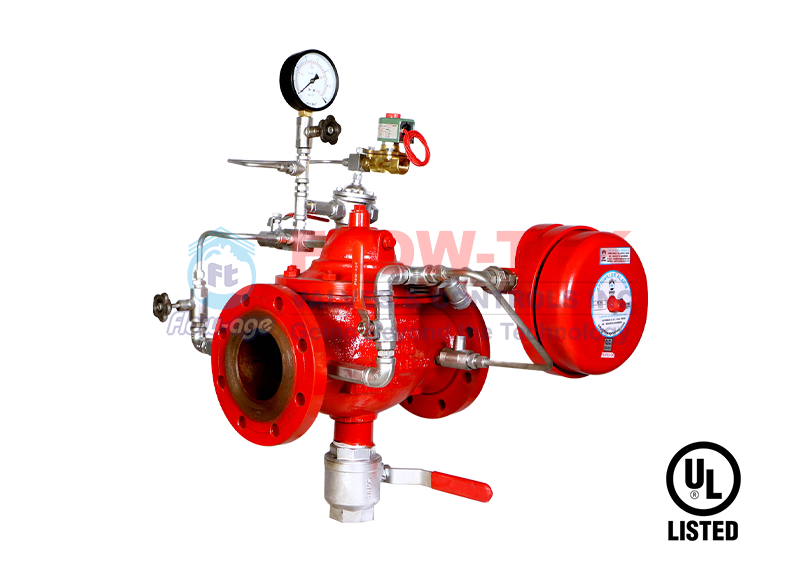

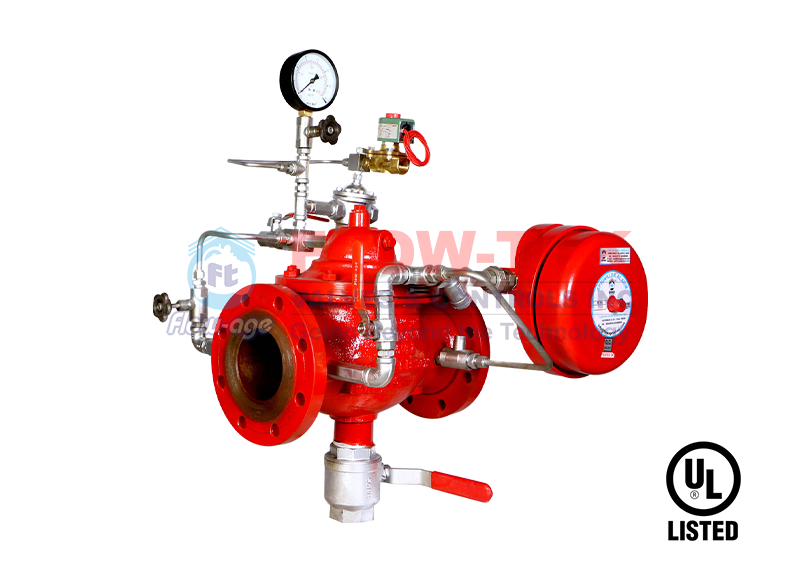

STRAIGHT TYPE DELUGE VALVE DETAIL -UL Listed

Local Resetting - Once the deluge valve operates, it is latched in an open position.

Remote Resetting - The FLOW TEK Deluge Valve can be remotely reset.

The FLOW TEK Deluge Valve is designed to allow for a variety of detection and release systems

Hydraulic Actuation (Wet Pilot Trim)

Wet pipe systems are the most common fire sprinkler system. A wet pipe system is one in which water is constantly maintained within the sprinkler piping. When a sprinkler activates this water is immediately discharged onto the fire.

Advantages to using a wet pipe fire sprinkler system include

- System simplicity and reliability - Wet pipe sprinkler systems have the least number of components and therefore, the lowest number of items to malfunction. This produces unexcelled reliability which is important since sprinklers may be asked to sit in waiting for many years before they are needed. This simplicity aspect also becomes important in facilities where system maintenance may not be performed with the desired frequency.

- Relative low installation and maintenance expense - Due to their overall simplicity, wet pipe sprinklers require the least amount of installation time and capital. Maintenance cost savings are also realized since less service time is generally required compared to other system types. These savings become important when maintenance budgets are shrinking.

- Ease of modification - Wet pipe fire sprinkler systems are advantageous since modifications involve shutting down the water supply, draining pipes and making alterations. Following the work, the system is pressure tested and restored. Additional work for detection and special control equipment is avoided which again saves time and expense.

- Short term down time following a fire - Wet pipe sprinkler systems require the least amount of effort to restore. In most instances, sprinkler protection is reinstated by replacing the fused sprinklers and turning the water supply back on. Pre-action and dry-pipe systems may require additional effort to reset control equipment.

Disadvantages to using a wet pipe fire sprinkler system include

- Wet pipe systems are not suited for sub-freezing environments.

- There may also be a concern where piping is subject to severe impact damage and could consequently leak.

Pneumatic Actuation (Dry Pilot Trim)

A dry pipe sprinkler system is one in which pipes are filled with pressurized air or nitrogen, rather than water. This air holds a remote valve, known as a dry pipe valve, in a closed position. Located in a heated space, the dry-pipe valve prevents water from entering the pipe until a fire causes one or more sprinklers to operate. Once this happens, the air escapes and the dry pipe valve releases. Water then enters the pipe, flowing through open sprinklers onto the fire.

Advantages of using dry pipe fire sprinkler systems include

- Dry pipe sprinkler systems provide automatic protection in spaces where freezing is possible. Typical dry pipe installations include unheated warehouses and attics, outside exposed loading docks and within commercial freezers. Many people view dry pipe sprinklers as advantageous for protection of collections and other water sensitive areas. This perceived benefit is due to a fear that a physically damaged wet pipe system will leak while dry pipe systems will not. In these situations, however, dry pipe systems will generally not offer any advantage over wet pipe systems. Should impact damage happen, there will only be a mild discharge delay, i.e. 1 minute, while air in the piping is released before water flow.

Disadvantages of using dry pipe fire sprinkler systems include

- Increased complexity - Dry pipe systems require additional control equipment and air pressure supply components which increases system complexity. Without proper maintenance this equipment may be less reliable than a comparable wet pipe system.

- Higher installation & maintenance costs - The added complexity impacts the overall dry-pipe installation cost. This complexity also increases maintenance expenditure, primarily due to added service labor costs

- Lower design flexibility - There are strict requirements regarding the maximum permitted size (typically 750 gallons) of individual dry-pipe systems. These limitations may impact the ability of an owner to make system additions.

- Increased fire response time - Up to 60 seconds may pass from the time a sprinkler opens until water is discharged onto the fire. This will delay fire extinguishing actions, which may produce increased content damage.

- Increased corrosion potential - Following operation, dry-pipe sprinkler systems must be completely drained and dried. Otherwise remaining water may cause pipe corrosion and premature failure. This is not a problem with wet pipe systems where water is constantly maintained in piping.

With the exception of unheated building spaces and freezer rooms, dry pipe systems do not offer any significant advantages over wet pipe systems.

Electric Actuation

VALVE WILL BE OPERATED BY SOLENOID VALVE, WHICH WILL BE OPERATED BY ANY POWER SUPPLY 220 V , 230 V , 24 V DC, ETC..