| Type | Wafer, full lug, uni-directional knife gate valve; rising stem hand wheel |

|---|---|

| Typical Applications | Medium & Heavy duty applications |

| Sizes available | 50-1200mm (2 to 48) |

| Pressure rating | |

| Cast iron body : | CWP 10 bar, 50-300mm (2"- 12") size; lower on higher sizes |

| Steel/St. steel : | CWP 10 bar, 50-600mm (2"- 24") size; lower on higher sizes |

| Face-to face | Complies with MSS SP-81 (upto 900mm (36") size) |

| Drilling | To suit ANSI 150lb,AS 2129 Table D & E, DIN PN10 (others on some sizes) |

| Material availability | standard; others on request |

| Body | WCB, CF8, CF8M, CF3, CF3M, CN7M, CD4MCuN, etc |

| Gate | 304, 316 st. steel (ANY OTHER MATEARIL AS PER REQUIRMENT) |

| Packing | PTFE syntex fiber standard; others on request |

| Seat / Leakage | Metal-to-metal - As per MSS SP-81 (upto 900mm (36") size |

| Resilient seats - EPDM, Chloroprene, Viton - Zero leak | |

| PTFE - Max leakage of 4cc/min/inch (upto 600mm (24") size | |

| Superstructure | Steel, epoxy painted |

| Handwheel | Cast iron, epoxy painted |

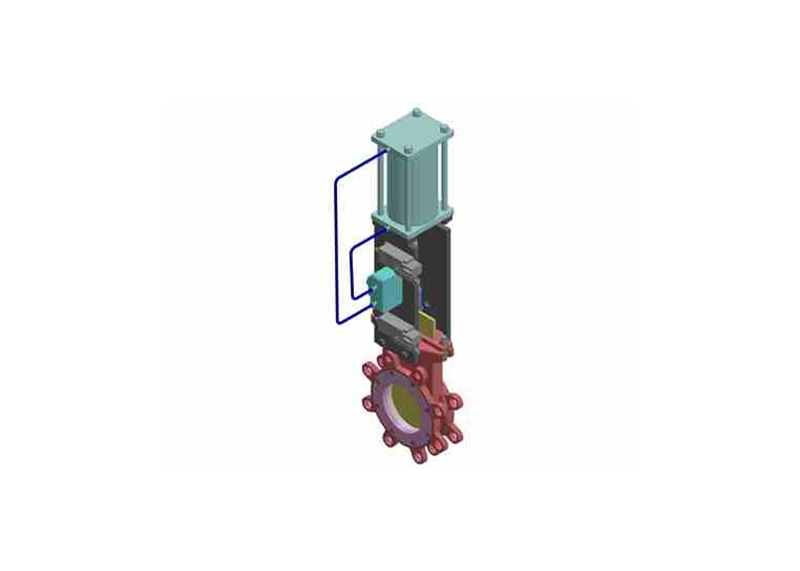

Features

Uni-Directional gate valves

Knife gate valve is one of the application-specific designs among industrial valves. These valves are designed to handle basically non-clean media with features that ensures minimum contact between moving parts of the valve. This is achieved by having a precision-ground gate that is held between layers of gland packing with almost no contact between the body parts and gate during most of its travel

The seating itself is accomplished with an almost non-sliding motion aided by jams located in the body. Avoiding sliding contact between gate and body permits this valve to handle abrasive particles present in the media much better than conventional designs. Another feature is the beveled bottom edge of the gate (from which it derives the 'knife' in its name) which allows positive closure of the gate even when solid particles settled at the bottom of the body.

In handling abrasive media, deflection cones are generally used in order to avoid direct impingement of the media on the seat surface; hard facing of body or seating parts is also sometimes used. Purge connections which let in suitable fluids at pressures higher than line pressure are Welded-jams with relieved inlet area also sometimes provided in these valves to clean seating surfaces(body purges) and packing area (chest purges). This minimizes abrasive wear and tear during valve opening and closure.

Knife gate valves are excellent hopper isolation valves with their ability to cut through flowing powders and close by dislodging any material in the seating area. This is also perhaps the only valve design which can tolerate differential thermal expansion of its parts without affecting its functions, thus making an ideal choice for handling high temperature media.

Applications

- Oil refineries.

- Water, steam, air, gas and liquids having corrosive properties.

- Suitable for wide range of working conditions of pressure and temperature ratings.