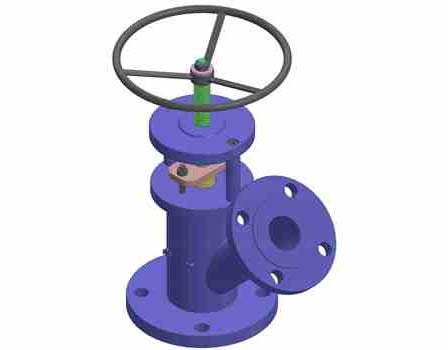

Y-TYPE FLUSH BOTTOM VALVE

Y-TYPE FLUSH BOTTOM VALVE

Flow-Tek" Flush Bottom Tank Valves, widely used for discharging materials from processing tanks, are designed so as to completely seal off the outlet nozzle at the inner vessel wall. This prevents solids from accumulating and solidifying in the outlet nozzle neck and stopping discharge of the vessel contents. It also prevents the collection of un-reacted material in the nozzle.

Flush Bottom Tank Valves have a modified 'Y' type body and Angel type design - with the stem being located in the vertical branch of the valve. Seat and disc design is similar to that of a globe valve with metal to metal seating. The disc can lift up from the seat and open into the vessel, or the disc can pull down from the seat and open into the valve.

All the valves are manufacturing as per international Design and standards to get the Total Interchangeable, Finest Quality and Workmanship.

AVAILABLE DESIGN FOR THE FLUSHBOTTOM

- Y TYPE FLUSH BOTTOM VALVE

- Y TYPE JACKETED FLUSH BOTTOM VALVE

- TEFLONE ( PFA , FEP ) LINIED FLUSH BOTTOM VALVE

- BALL TYPE FLUSH BOTTOM VALVE ( JACKETED AND NON JACKETED)

- Unique design of "Flow-Tek" flush bottom valves assure "Zero- Hold Up" in the bottom pad of the tank. And facilitate the free flow and quick discharge of the liquid or slurry through the valves.

- Casted and fabricated in all available metallurgy, Carbon Steel, S.S 304, S.S 316, S.S 304L, S.S 316L, Alloy 20, Hast alloy and as per special specifications.

- Conical Metal to Metal disc seating/ PTFE seating with option of fixed or Renewable seat. Further metal seating can be hard faced by Satellite TM where distortion of seat by aggressive liquid or slurry is common.

- Valves available in the size range of 15 NB to 250 NB in BS, ANSI & DIN standards.

- Available in the design of Jacketed, Actuated & Lined.

- Offered for Sanitary aseptic application.

- Outlet discharge angle available in 450and can also be tailored made to 600.

- "FLOW-TEK" Flush Bottom vales can also be provided with the temperature sensors to measure the temperature in the vessel.

- Bolted Stuffing Box (Gland), easily adjustable & with Replaceable service.

- Rinsing & Non Rinsing stem with outside ACME thread.

- End Connections - Screwed, flange, Socket weld, TCV joints etc.

VALVE OPERATION

| OPERATOR | Size Range |

|---|---|

| HAND WHEEL | 1" - 12" - Class 150, 300#, 600# |

| ELECTRICALLY CONTROLLED, | 1" - 24" - Class 150, 300#, 600# |

| GEAR OPERATED, CHAIN OPERATED - | 1" - 24" - Class 150, 300#, 600# |

| GEAR OPERATOR | 1" - 24" - Class 150, 300#, 600# |

- PROCESS INDUSTRIES

- PHARMACEUTICAL

- Bio and food grad products

- FERTILIZER

- Lime (CEMENT)

- RESINE

- chemicals or other abrasive

- corrosive slurry

- Liquid with solid suspensions and many others media which are difficult to handle with seat valve.

![]()